Izitini eziphikisayo ezimelana nokushisa okuphezulu kwamaKilns, amafurnaces

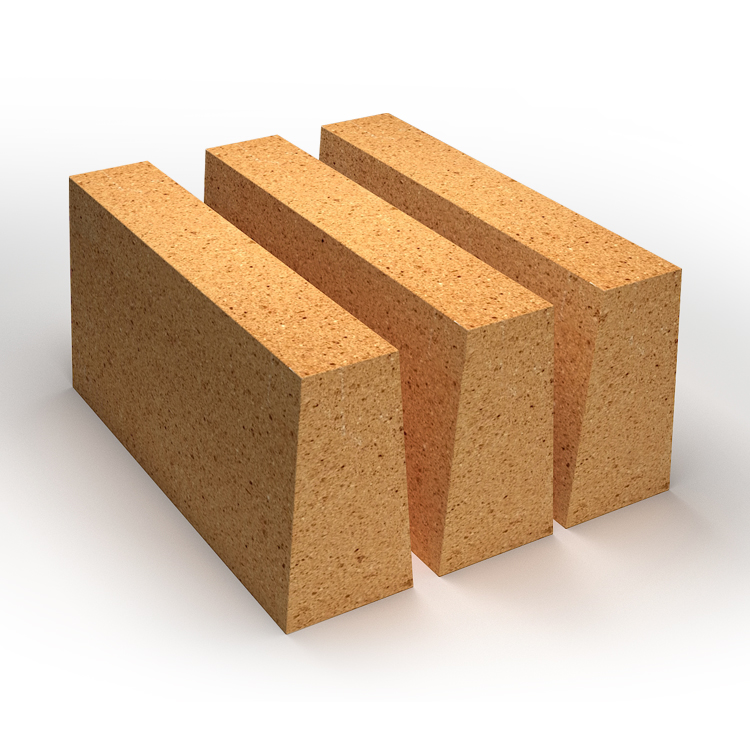

Ngokwezingxenye ezihlukene zezitini eziphikisayo, zingahlukaniswa zibe izigaba ezinhlanu, okungukuthi: izitini ze-silicon-alumina zochungechunge lwe-refractory, izitini ze-alkaline eziphikisayo, izitini eziphikisayo ezine-carbon, izitini eziphikisayo eziqukethe i-zirconium, nezitini ze-refractory ezivimbela ukushisa.

Noma yisiphi isithando somlilo asikhiwanga ngohlobo olulodwa kuphela lwezitini eziphikisayo, sidinga inhlanganisela yezitini ezihlukene eziphikisayo.

(1)Izitini zesilika zibhekisela ezitini eziphikisayo eziqukethe ngaphezu kuka-93% SiO2, okuyizinhlobo eziyinhloko zezitini eziphikisa i-asidi.Isetshenziselwa ikakhulukazi ohhavini be-masonry coke, kodwa futhi nakuma-vaults nezinye izingxenye ezithwala imithwalo yeziko ezishisayo zengilazi ehlukahlukene, ama-ceramics, ama-carbon calciners, nezitini eziphikisayo.Isetshenziswa ezintweni ezishisayo ezingaphansi kuka-600 ° C futhi ngokushintshashintsha okukhulu kwezinga lokushisa.

(2)Izitini zobumba.Izitini zobumba ikakhulukazi zakhiwe i-mullite (25% kuya ku-50%), isigaba sengilazi (25% kuya ku-60%), ne-cristobalite ne-quartz (kufika ku-30%).Ngokuvamile, ubumba oluqinile lusetshenziswa njengempahla eluhlaza, i-clinker ibalwa kusengaphambili bese ihlanganiswa nobumba oluthambile.Isamba esincane sengilazi yamanzi, usimende, nezinye izinto zokuhlanganisa nazo zingafakwa ukuze kwenziwe imikhiqizo engashiswanga nezinto ezingakakhiwe.Kuyisitini esisetshenziswa ngokujwayelekile ezithandweni eziqhumayo, izitofu ezishisayo, iziko lokushisisa, amaboiler kagesi, okokhela umcako, okhini abajikelezayo, izitsha zobumba, kanye neziko lomlilo lezitini eziphikisayo.

(3) Izitini eziphezulu ze-alumina refractory.Ukwakheka kwamaminerali kwezitini eziphikisayo ze-alumina ephezulu yizigaba ze-corundum, mullite, nengilazi.Izinto zokusetshenziswa ziyi-high-alumina bauxite ne-sillimanite ore yemvelo, futhi kukhona ne-corundum ehlanganisiwe, i-alumina ehlanganisiwe, i-synthetic mullite, ne-clinker calcined nge-alumina nobumba ngezilinganiso ezahlukene.Ikhiqizwa kakhulu indlela ye-sintering.Kodwa le mikhiqizo ihlanganisa nezitini eziphonsiwe ezihlanganisiwe, izitini ezihlanganisiwe, izitini ezingashiswanga, nezitini eziphikisayo ezingabunjiwe.Izitini eziphezulu ze-alumina refractory zisetshenziswa kakhulu embonini yensimbi neyensimbi, embonini yensimbi engeyona insimbi, nezinye izimboni.(4) Izitini ze-Corundum refractory, izitini ze-corundum zibhekisela ohlotsheni lwezitini eziyi-refractory ezinokuqukethwe kwe-AL2O3 okungengaphansi kuka-90% kanye ne-corundum njengesigaba esiyinhloko, esingahlukaniswa ngezitini ze-corundum ezihlanganisiwe nezitini ze-corundum (5) Eziphakeme- i-alumina-insulating light-weight refractory izitini.Kuyisitena esivikela ukukhanya esivikelayo esine-bauxite njengokuqukethwe okuyinhloko kwe-AL2O3 okungengaphansi kwama-48%.Inqubo yokukhiqiza isebenzisa indlela yegwebu, futhi indlela yokwengeza yokushiswa ingasetshenziswa.Izitini eziphikisa ukushisa ezine-alumina ephezulu zingasetshenziswa ukwakha izendlalelo ezivikela ukushisa kanye nezindawo lapho kungekho khona ukuguguleka kwempahla encibilikisiwe eqinile enamazinga okushisa aphezulu kanye nokukhuhla.Uma uthintana ngqo nelangabi, izinga lokushisa elingaphezulu kwezitini eziphikisayo ezivikela ukushisa ze-alumina akumele libe ngaphezu kuka-1350 ℃.Izitini ze-Mullite ezivimbela ukushisa zingathintana ngqo nelangabi futhi zibe nezici zokumelana nezinga lokushisa eliphezulu, amandla aphezulu, nomphumela ophawulekayo wokonga amandla.Ifanele ulwelwesi lwesithando somlilo se-pyrolysis, isithando somlilo esishisayo, i-ceramic roller kiln, i-electric porcelain drawer kiln, kanye nezithando ezihlukahlukene zokumelana.(6) Izitini eziphikisayo ezivikela ukushisa zobumba ezingasindi yizitini eziphikisa ukushisa ezinokuqukethwe kwe-AL2O3 okungu-30% kuya ku-48% ezenziwe ngobumba obuphikisayo njengento eluhlaza eyinhloko.Inqubo yayo yokukhiqiza isebenzisa indlela yokushiswa kwezinhlamvu kanye nendlela yegwebu.Kusetshenziswa ubumba oluphikisayo, ubuhlalu obuntantayo, kanye ne-clinker yobumba ephikisayo njengezinto zokusetshenziswa, ukwengeza i-binder kanye ne-sawdust, ngokuhlanganisa, ukuxuba, ukubumba, ukomisa, nokudubula, umkhiqizo onobuningi obukhulu obungu-0.3 kuya ku-1.5g/cm3 utholakala.Ukukhishwa kwezitini zobumba zokushisa ukushisa kubalwa ngaphezu kwengxenye yokukhishwa okuphelele kwezitini eziphikisayo zokushisa ukushisa.

Isetshenziswa kakhulu kuhhavini oqhumayo, iziqhumiso ezishisayo, izithando zokushisa, iziko lensimbi, ohhavini be-coke, ama-carbon furnaces, i-ladle, ama-ladle casting systems, ama-boilers, izishishi zikasimende, izikloni zengilazi, iziko lokushibilika komhubhe, okokhela okujikelezayo, nokushisa kwe-shaft nezinye iziko lomlilo. kanye nemishini eshisayo isetshenziswa kabanzi kwezensimbi, embonini yamakhemikhali, i-ceramics, i-coking, i-carbon, i-casting, imishini, amandla kagesi, izinto zokwakha, i-petroleum, nezinye izimboni.