Embonini ye-aluminium foundry, ukusetshenziswa kwe-aluminium ceramic launder ukudlulisa i-aluminium encibilikisiwe kubalulekile ekuqinisekiseni inqubo yokukhiqiza eshelelayo nephumelelayo.Isiwashi se-ceramic esiklanywe kahle futhi esisebenza kahle singathuthukisa kakhulu ikhwalithi ye-metallurgical yokusakaza futhi sibambe iqhaza ekongeni amandla.

An i-aluminium yokuhlanza i-ceramic iwumzila osetshenziselwa ukudlulisa i-aluminium encibilikisiwe isuka esithandweni iye endaweni yokubunjwa.Idlala indima ebalulekile ekugcineni ubuqotho be-aluminium ewuketshezi nokuqinisekisa ukuthi ifinyelela isikhunta.Ukuklanywa nokwakhiwa kwe-ceramic launder kubalulekile ekufezeni lezi zinhloso.

Enye yezinzuzo eziyinhloko zokusebenzisa i-aluminium launder ceramic enqubweni yokuphonsa amandla ayo okwehlisa izinga lokushisa le-aluminium encibilikisiwe.Ngokuqondisa uketshezi ngokusebenzisa izingubo zokuhlanza ezifakwe kahle nezifakwe kulayini, izinga lokushisa lingalawuleka kangcono, livimbele ukushisa ngokweqile.Lokhu kubaluleke kakhulu ekukhiqizeni ukulingisa kwekhwalithi ephezulu ngezakhiwo ezifiselekayo.

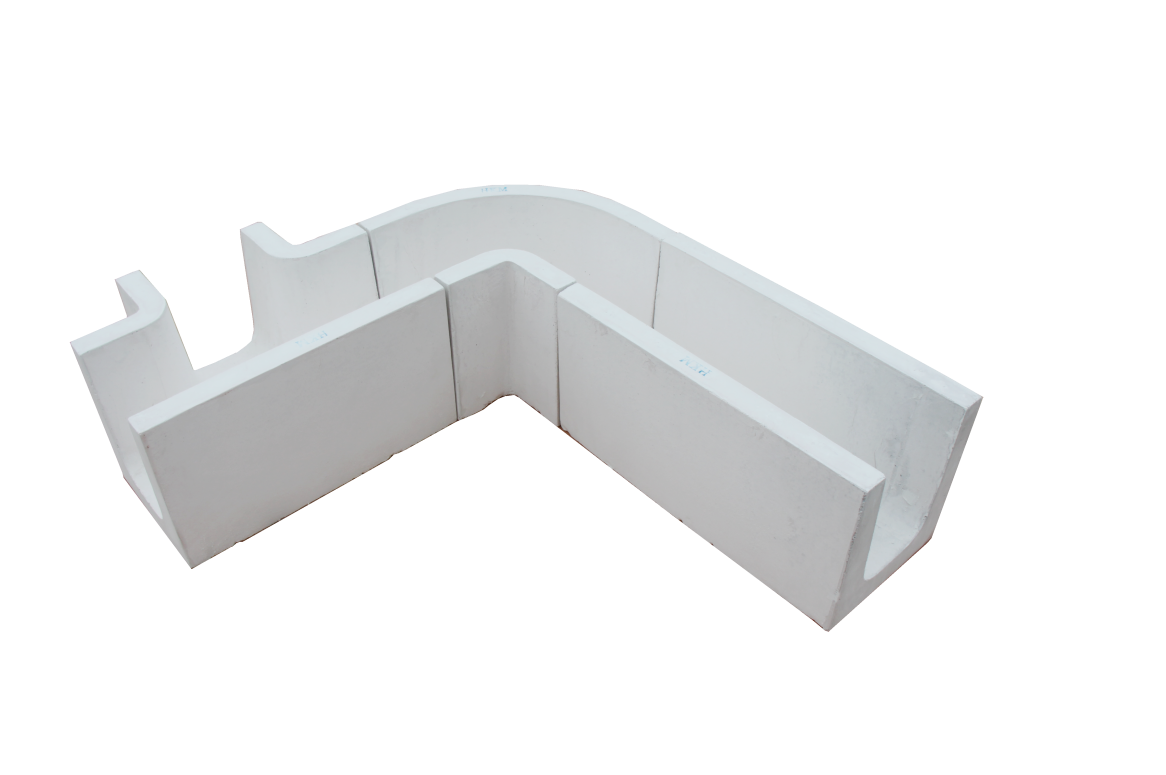

Ngaphandle kwale misebenzi eyisisekelo, iziwashi ze-aluminiyamu ze-ceramic ziza ngezinhlobonhlobo zomumo ukuze zivumelane nokusetha okuhlukile kwe-Foundry kanye nezidingo.Ukuthi i-flow groove inezimo ezihlukahlukene ezifana ne-DC groove, indololwane, i-tee, isiphambano nokunye, ukwakheka kwe-ceramic launder kungaba cu.

stomized ukuhlangabezana nezidingo ezithile zenqubo yokulingisa.Ngaphezu kwalokho, ulwelwesi lwe-launder luklanyelwe ukuba lube nobuso obushelelezi, obungagcini nje ngokuhambisana nokugeleza okubushelelezi kwe-aluminium encibilikisiwe, kodwa futhi kunomthelela ekuphikiseni ukushaqeka kwayo okushisayo.Lokhu kubalulekile njengoba izinga lokushisa elingazinzile lingabangela ukuqhekeka kanye nokulimala kumshini wokuwasha.

Enye impahla ebalulekile ye-aluminium ceramic launder impilo yabo ende yenkonzo.I-lining material esetshenzisiwe ikhethiwe ngenxa yokuqina kwayo kanye nekhono lokumelana nezimo ezinzima zemvelo ye-Foundry.Lokhu kuqinisekisa ukusebenza kahle kwesikhathi eside kwesiwashi, kunciphisa isikhathi sokuphumula kanye nezindleko zokuyilungisa.

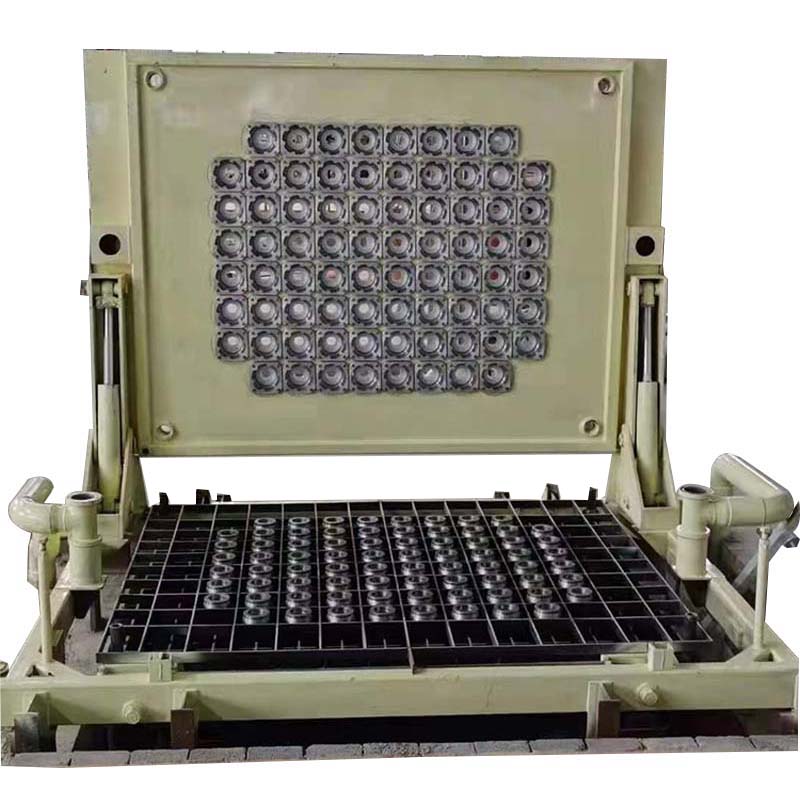

Ngaphezu kwalokho, i-lining material ye-aluminium ceramic launder yenziwe ngokukhethekile ukuze inganamatheli ku-aluminium.Lokhu kusho ukuthi i-aluminium encibilikisiwe ayinamatheli kulayini, le mpahla enganamathele isiza futhi ukuthuthukisa ikhwalithi yokubunjwa.Kwehot top casting inqubo,

ungqimba oluncane lwei-talcum powder kufanele kusakazwe kumshini wokuwasha ngaphambi kokubunjwa, akufanele kube nezingcezu zensimbi eziveziwe futhi umgudu lapho i-aluminium encibilikisiwe idlula kufanele igcinwe ihlanzekile futhi yomile, okuvumela ukugeleza okubushelelezi, okuqhubekayo.

Kafushane, ukusetshenziswa kwe-aluminum ceramic launder enqubweni yokuphonsa i-aluminium kubalulekile ekudluliseni i-aluminium encibilikisiwe.Akugcini nje ukuthuthukisa izinga le-metallurgical of castings, kodwa futhi linomthelela ekongeni amandla.Ikhono lokunciphisa izinga lokushisa le-aluminium encibilikisiwe, ukuvikela izakhi ze-alloying yizinzuzo ezibalulekile zokusebenzisa i-aluminium launder ceramic.Ngokusebenzisa izinto ezithuthukisiwe ezinamandla amakhulu, ukumelana nokugqwala kanye nokumelana nokushaqeka okushisayo, isiwashi se-ceramic siqinisekisa impilo ende yesevisi futhi sinciphisa isikhathi sokuphumula.Ngezindawo zayo ezingezona izinduku, i-ceramic launder iphinde isize ekuvimbeleni ukungcola futhi iqinisekise ukukhiqizwa kokusakazwa kwekhwalithi ephezulu.

Isikhathi sokuthumela: Aug-16-2023