I. ukufinyeza

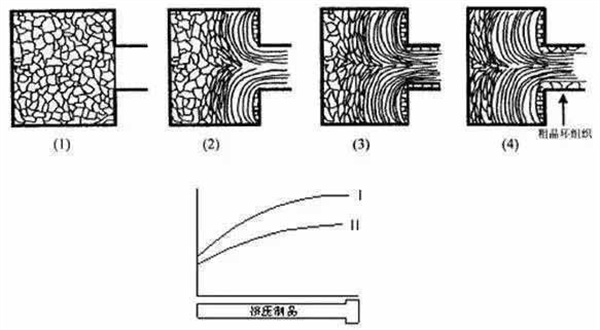

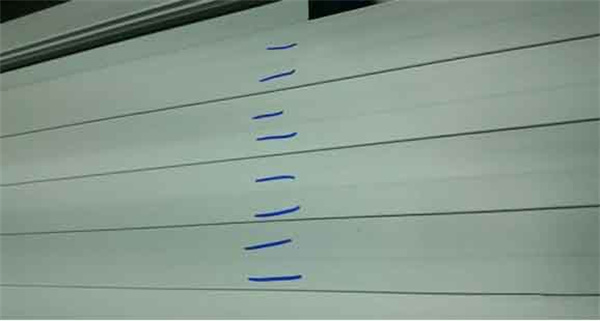

Ekupheleni komsila weminye imikhiqizo ekhishwe, ngemva kokuhlolwa kokukhuliswa okuphansi, kukhona into efana nophondo engxenyeni ephakathi nendawo yesiphambano, ebizwa ngokuthi umsila onciphayo.

Ngokuvamile, umsila womkhiqizo we-extrusion wangaphambili mude kunalowo we-reverse extrusion, futhi i-alloy ethambile yinde kune-alloy eqinile.Ukushwabana komkhiqizo osuselwe phambili ikakhulukazi kusesimweni songqimba lwe-annular disjoint, futhi ukushwabana komkhiqizo okhishiwe okuphambene ngokuvamile kusesimweni sefaneli emaphakathi.

Insimbi idluliselwa ekugcineni kwangemuva, futhi isikhumba se-ingot kanye nokufakwa kwamanye amazwe kuqoqwe ekhoneni elifile le-cylinder extrusion noma i-gasket igeleza emkhiqizweni ukuze yenze i-shrinkage yesibili;lapho impahla eyinsalela imfushane kakhulu futhi isikhungo somkhiqizo singaphakelwa ngokwanele, ifomu uhlobo lwesifinyezo.Kusukela ekugcineni komsila kuya phambili, umsila kancane kancane uba lula futhi unyamalale ngokuphelele.

Imbangela enkulu yokuncipha

1. Impahla eyinsalela imfushane kakhulu noma ubude bomkhawulo osikiwe womkhiqizo abuhlangabezani nemithethonqubo;

2. I-extrusion pad ayihlanzekile futhi inamabala amafutha;

3. Esigabeni sakamuva se-extrusion, isivinini se-extrusion sishesha kakhulu noma sikhuphuka ngokuzumayo;

4. Sebenzisa iphedi yokukhama ekhubazekile (iphedi eliphakanyisiwe phakathi nendawo);

5. Izinga lokushisa le-cylinder extrusion liphezulu kakhulu;

6. I-cylinder extrusion kanye ne-extrusion shaft ayihambisani;

7. Ubuso be-ingot abuhlanzekile, kukhona amabala amafutha, izimila zokuhlukanisa nokugoqa nezinye iziphambeko azisuswanga;

8. Umkhono wangaphakathi we-cylinder extrusion awuhlanzekile noma ukhubazekile, futhi i-lining yangaphakathi ayihlanzwa nge-pad yokuhlanza ngesikhathi.

Indlela yokuvimbela

1. Shiya izinsalela futhi usike imisila njengoba kudingeka;

2. Gcina isikhunta sihlanzekile;

3. Thuthukisa izinga eliphezulu le-ingot;

4. Lawula ngokunengqondo izinga lokushisa nesivinini ukuze uqinisekise ukuphuma okubushelelezi;

5. Ngaphandle kwezimo ezikhethekile, kwenqatshelwe ngokuphelele ukusebenzisa amafutha ebusweni bethuluzi kanye nesikhunta;

6. I-gasket ipholiswe kahle.

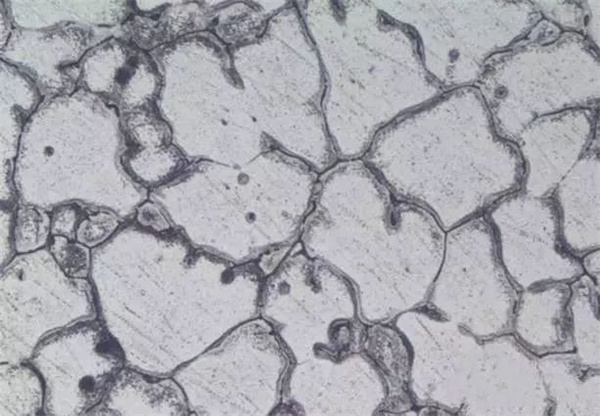

II.Indandatho yekristalu eqinile

Eminye imikhiqizo ye-aluminium extruded alloy yakha indawo yesakhiwo sokusanhlamvu esimahhadlahhaza eduze kwendawo ezungezile yomkhiqizo ocezwini lokuhlola lokukhuliswa okuphansi ngemva kokwelashwa kwesixazululo, okubizwa ngokuthi indandatho yokusanhlamvu eqinile.Ngenxa yokubunjwa okuhlukene nezindlela zokucubungula zemikhiqizo, okumise okwendandatho, okumise okwe-arc nezinye izinhlobo zamasongo anezinhlamvu eziqinile zingakhiwa.Ukujula kwendandatho enohlamvu olumahhadla kancane kancane kuncipha ukusuka emsileni kuya phambili futhi kunyamalale ngokuphelele.Indlela yokwakheka eyinhloko isifunda sokusanhlamvu esincane esakhiwe phezu komkhiqizo ngemva kokukhishwa okushisayo, futhi isifunda sokusanhlamvu esimahhadlahhaza sakhiwa ngemva kokushisisa nokwelashwa kwesixazululo.

Imbangela eyinhloko yeringi yekristalu eqinile

1. I-extrusion deformation engalingani

2. Izinga lokushisa lokwelapha ukushisa liphezulu kakhulu futhi isikhathi sokubamba side kakhulu, ukuze izinhlamvu zikhule;

3. Ukwakheka kwamakhemikhali egolide akunangqondo;

4. Ama-alloys ajwayelekile okuqinisa ukushisa aphethwe ukushisa anezindandatho ezinohlamvu oluqinile ngemva kokwelashwa kokushisa, ikakhulukazi ukubunjwa kanye nemigoqo ye-6a02, 2a50 kanye namanye ama-alloys yizona ezibucayi kakhulu, ezingenakuqedwa futhi zingalawulwa kuphela phakathi kwebanga elithile;

5. I-extrusion deformation incane noma i-deformation ayanele, noma ebangeni elibucayi lokuguqulwa, futhi kulula ukukhiqiza indandatho ye-crystal eqinile.

Indlela yokuvimbela

1. Udonga lwangaphakathi lwesilinda e-extrusion lubushelelezi futhi luhlanzekile, lwakha umkhono ophelele we-aluminium ukuze unciphise ukungqubuzana ngesikhathi sokukhipha;

2. Ukuguqulwa kufanele kugcwele futhi kufane ngangokunokwenzeka, futhi imingcele yenqubo efana nezinga lokushisa nesivinini kufanele ilawulwe ngokunengqondo;

3. Gwema izinga lokushisa lokwelashwa kwesisombululo liphezulu kakhulu noma isikhathi sokubamba side kakhulu;

4. Ukukhipha ngembobo yokufa;

5. I-Extrusion by reverse extrusion method kanye nendlela ye-static extrusion;

6. Ikhiqizwe ngesixazululo indlela yokwelapha-ukudweba-ukuguga;

7. Lungisa isamba sokwakheka kwegolide futhi wandise i-recrystallization inhibitory element;

8. Sebenzisa i-extrusion yokushisa ephezulu;

9. Amanye ama-alloy ingots awenziwanga i-homogenized, futhi indandatho yokusanhlamvu eqinile ayishoni ngesikhathi sokukhishwa.

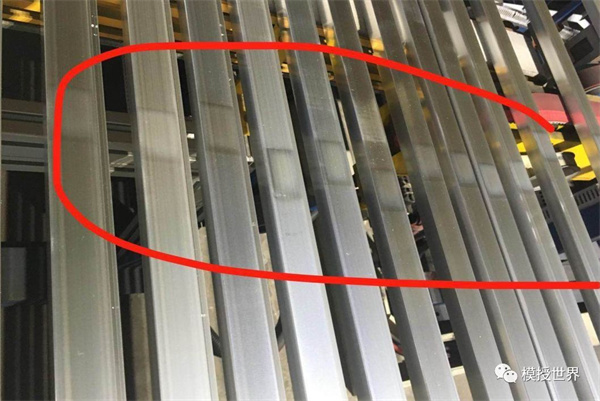

III, ungqimba

Lesi yisici sesikhumba se-delamination esakhiwe lapho ukugeleza kwensimbi kufana ngokuqhathaniswa, futhi ingaphezulu le-ingot ligelezela emkhiqizweni eduze kwesixhumi esibonakalayo phakathi kwesikhunta nendawo yokunwebeka yangaphambili.Esiqeshini esiphambanayo sokukhulisa okuphansi, kubonakala sengathi kukhona iphutha lezendlalelo ezihlukene emaphethelweni esigaba esiphambene.

Imbangela eyinhloko ye-stratification

1. Kukhona uthuli ebusweni be-ingot noma i-ingot inezigaba ezinkulu zokuhlukanisa esikhundleni sesikhumba semoto, izimila zensimbi, njll, okulula ukwenza izendlalelo;

2. Kukhona ama-burrs ebusweni bokungenalutho noma ukungcola okufana namabala amafutha, sawdust, njll, okungahlanzwa ngaphambi kokukhipha;

3. Isikhundla somgodi wokufa asinangqondo, eduze nomkhawulo we-cylinder extrusion;

4. Ithuluzi le-extrusion ligugile kakhulu noma kukhona ukungcola esihlahleni se-cylinder extrusion, engakwazi ukuhlanzwa nokushintshwa ngesikhathi;

5. Umehluko wobubanzi bephedi ye-extrusion mkhulu kakhulu;

6. Izinga lokushisa le-cylinder extrusion liphakeme kakhulu kune-ingot.

Indlela yokuvimbela

1. Ukuklama okunengqondo kwezikhunta, ukuhlolwa okufika ngesikhathi kanye nokushintshwa kwamathuluzi angafanelekile;

2. Ama-ingots angafanelekile awafakiwe esithandweni;

3. Ngemuva kokusika izinto ezisele, kufanele zihlanzwe ngaphandle kokunamathela kumafutha okugcoba;

4. Gcina ulwelwesi lwesilinda sokukhipha luqinile, noma hlanza ulwelwesi ngesikhathi nge-gasket.

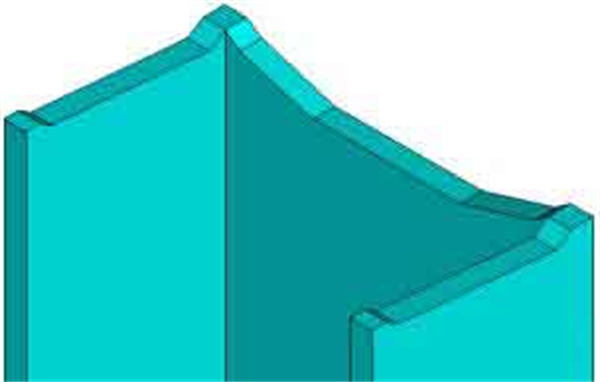

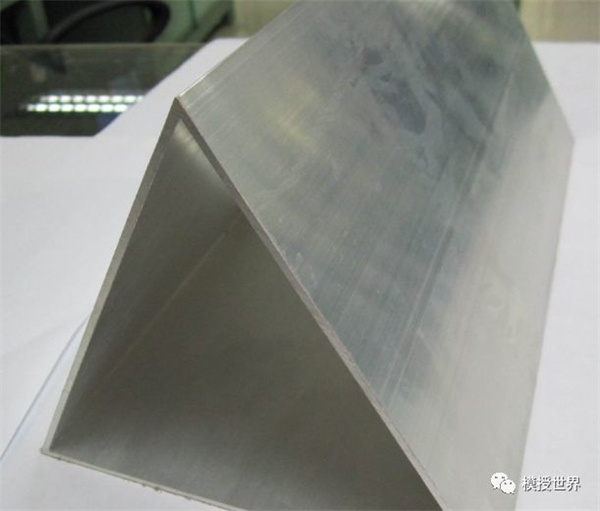

IV.Ukushisela okubi

Ukwenzeka kwe-weld delamination noma ukushisela okungaphelele komkhiqizo ongenalutho okhishwe yi-split die at the weld kubizwa ngokuthi ukushisela okungalungile.

Imbangela eyinhloko yokushisela okubi

1. I-extrusion coefficient incane, izinga lokushisa le-extrusion liphansi, futhi isivinini se-extrusion siyashesha;

2. Uboya bokukhipha noma amathuluzi awahlanzekile;

3. Oyela isikhunta;

4. Idizayini yesikhunta engalungile, ingcindezi ye-hydrostatic enganele noma engalingani, ukuklama okungenangqondo kwezimbobo ze-shunt;

5. Kukhona ibala lamafutha ebusweni be-ingot.

Indlela yokuvimbela

1. Khulisa kahle i-coefficient ye-extrusion, izinga lokushisa le-extrusion kanye nesivinini sokukhipha;

2. Ukuklama okunengqondo kanye nokukhiqizwa kwesikhunta;

3. I-extrusion cylinder kanye ne-extrusion gasket ayigcotshiwe futhi igcinwe ihlanzekile;

4. Sebenzisa ama-ingots anezindawo ezihlanzekile.

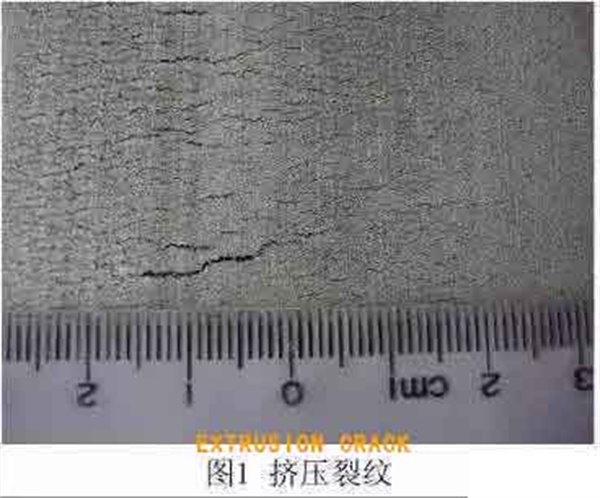

V. Imifantu ye-Extrusion

Lokhu ukuqhekeka okuncane okumise okwe-arc onqenqemeni locezu lokuhlola oluguquguqukayo lomkhiqizo okhishiwe, kanye nokuqhekeka ngezikhathi ezithile nge-engeli ethile eduze nendawo yayo ye-longitudinal, efihlwe ngaphansi kwe-epidermis ezimweni ezikhanyayo, kanye nemifantu e-serrated ungqimba olungaphandle. ezimweni ezimbi kakhulu, okuzolimaza kakhulu ukuqhubeka kwensimbi.Ukuqhekeka kwe-Extrusion kwakheka lapho ingaphezulu lensimbi lidatshulwa ukucindezelwa okuqinile kwezikhathi ezithile kodonga lokufa ngesikhathi senqubo yokukhipha.

Isizathu esiyinhloko sokuqhekeka kwe-extrusion

1. Isivinini sokukhipha sishesha kakhulu;

2. Izinga lokushisa lokukhipha liphezulu kakhulu;

3. Ijubane le-extrusion liyashintshashintsha kakhulu;

4. Izinga lokushisa loboya obukhishwe liphezulu kakhulu;

5. Uma i-porous die extruded, ukuhlelwa kwe-die kusondele kakhulu phakathi nendawo, ukuze ukunikezwa kwensimbi okuphakathi kunganele, ukuze umehluko phakathi kwesikhungo kanye nesilinganiso sokugeleza komphetho mkhulu kakhulu;

6. I-ingot homogenization annealing ayilungile.

Indlela yokuvimbela

1. Sebenzisa ngokuqinile ukucaciswa okuhlukahlukene kokushisisa nokukhipha;

2. Ukuhlolwa njalo kwezinsimbi nezinto zokusebenza ukuze kuqinisekiswe ukusebenza okuvamile;

3. Shintsha umklamo wesikhunta futhi uwucubungule ngokucophelela, ikakhulukazi umklamo webhuloho lokukhunta, igumbi lokushisela kanye ne-edge radius, njll. kufanele kube okunengqondo;

4. Nciphisa okuqukethwe kwe-sodium kuma-alloys aphezulu e-magnesium aluminium;

5. Ingot yenziwe i-homogenized futhi ifakwe i-anneal ukuze ithuthukise ipulasitiki yayo nokufana.

VI.Amabhamuza

Insimbi yesikhumba yasendaweni ihlukaniswa ngokuqhubekayo noma ngokungaqhubeki nesisekelo sensimbi, futhi ibonakala njengesiyingi esiyisiyingi esisodwa noma isici esimise okumise okwe-strip, esibizwa ngokuthi ibhamuza.

Imbangela enkulu yamabhamuza

1. Uma i-extruding, i-cylinder extrusion kanye ne-extrusion pad inokungcola okunjengomswakama namafutha;

2. Ngenxa yokugqoka kwe-cylinder extrusion, umoya phakathi kwengxenye egugile kanye ne-ingot ingena endaweni yensimbi ngesikhathi sokukhipha;

3. Kunomswakama endaweni yokugcoba;

4. Isakhiwo se-ingot ngokwaso sinokukhubazeka okuxekethile kanye ne-porosity;

5. Izinga lokushisa lokwelapha ukushisa liphezulu kakhulu, isikhathi sokubamba side kakhulu, futhi umswakama womkhathi esithandweni uphakeme;

6. Okuqukethwe kwe-hydrogen emkhiqizweni kuphezulu kakhulu;

7. Izinga lokushisa le-cylinder ye-Extrusion kanye nezinga lokushisa le-ingot liphezulu kakhulu.

Indlela yokuvimbela

1. Izingxenye ezingaphezulu zamathuluzi nama-ingots kufanele zigcinwe zihlanzekile, zibushelelezi futhi zomile;

2. Yakha ngokunengqondo usayizi ofanayo we-cylinder extrusion kanye ne-extrusion gasket, hlola ubukhulu bethuluzi njalo, lungisa isilinda sokukhipha ngesikhathi lapho kunesisu esikhulu, futhi i-gasket ye-extrusion akufanele iphelelwe ukubekezelelana;

3. Qinisekisa ukuthi okokugcoba kuhlanzekile futhi komile;

4. Ukuhambisana ngokuqinile nenqubo yokusebenza kwenqubo ye-extrusion, khipha ngesikhathi, usike ngendlela efanele, ungasebenzisi amafutha, susa ngokuphelele izinto ezisele, gcina izikhala nezibunjwa zihlanzekile futhi zingangcolisiwe.

VII.Ukucwecwa

Lesi yisenzakalo sokuhlukaniswa kwendawo phakathi kwensimbi yesikhumba kanye nesisekelo sensimbi yomkhiqizo we-aluminium alloy extrusion.

Imbangela enkulu yokuxebuka

1. Uma i-alloy ithathelwa indawo futhi ikhishwe, udonga lwangaphakathi lwesilinda e-extrusion lunamathele esihlahleni esakhiwe yinsimbi yokuqala, engahlanjululwa kahle;

2. I-cylinder extrusion kanye ne-extrusion pad ayihambisani kahle, futhi udonga lwangaphakathi lwe-cylinder extrusion luhlanganiswe nensimbi yendawo yokuhlala;

3. Ikhishwa nge-lubricating extrusion cylinder;

4. Kukhona insimbi emgodini wokufa noma ibhande elisebenzayo le-die lide kakhulu.

Indlela yokuvimbela

1. Hlanza kahle i-cylinder extrusion lapho ukhipha i-alloy;

2. Yakha ngokunengqondo usayizi ofanayo wesilinda sokukhipha kanye ne-extrusion gasket, hlola usayizi wethuluzi njalo, futhi i-extrusion gasket ayikwazi ukubekezelela;

3. Hlanza insimbi esele esibunjeni ngesikhathi.

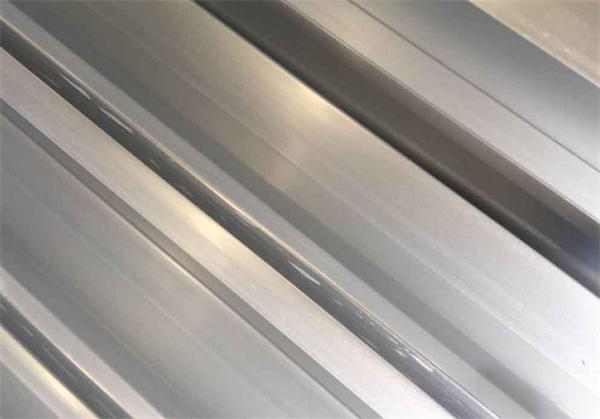

VIII.Ukuklwebheka

Izibazi zomshini ezinomugqa owodwa ezibangelwa ukuthintana phakathi kwezinto ezicijile kanye nobuso bomkhiqizo ngesikhathi sokushelela okuhlobene zibizwa ngokuthi imihuzuko.

Imbangela enkulu yemihuzuko

1. Ukuhlanganiswa okungalungile kwamathuluzi, iziqondiso ezingaguquki kanye namatafula okusebenza, amakhona abukhali noma izinto zangaphandle, njll.;

2. Kukhona ama-chips ensimbi ebhande elisebenzayo lesikhunta noma ibhande elisebenzayo lesikhunta lonakele;

3. Kunesihlabathi noma ama-chips ensimbi aphukile emafutheni okugcoba;

4. Ukusebenza okungalungile ngesikhathi sokuthutha kanye ne-spreader engalungile.

Indlela yokuvimbela

1. Hlola futhi upholishe ibhande elisebenzayo lesikhunta kusenesikhathi;

2. Hlola umzila wokuphuma komkhiqizo, kufanele ube bushelelezi, futhi indlela yokuqondisa ingagcotshwa ngendlela efanele;

3. Vimbela ukuhlikihlwa nokwanwaya ngomshini ngesikhathi sokuphatha.

IX.Amaqhuqhuva

Izibazi ezakhiwe ebusweni bemikhiqizo noma imikhiqizo eshayisane nezinye izinto zibizwa ngokuthi ukulimala kwamaqhubu.

Imbangela enkulu yamaqhubu

1. Isakhiwo sebhentshi lokusebenzela kanye nokubeka izinto ezibonakalayo akunangqondo;

2. Ukuvikelwa kwensimbi okungalungile kobhasikidi bezinto, ama-racks wezinto ezibonakalayo, njll.;

3. Ungayiphathi ngokucophelela lapho usebenza.

Indlela yokuvimbela

1. Ukusebenza ngokucophelela, phatha ngokucophelela;

2. Gaya amakhona acijile, bese uvala ubhasikidi ne-rack nge-dunnage nezinto ezithambile.

X. Ukuklwebheka

Izibazi ezisatshalaliswe ngezinqwaba ebusweni bomkhiqizo okubangelwa ukushelela okuhlobene noma ukugudluka ngemva kokuthi indawo yomkhiqizo okhishiwe ihlangane nemiphetho noma ezinye izinto ibizwa ngokuthi imihuzuko.

Imbangela enkulu yemihuzuko

1. Isikhunta sigqokwe sina;

2. Ngenxa yokushisa okuphezulu kwe-ingot, imbobo yokufa inamathela ku-aluminium noma ibhande elisebenzayo le-die hole lonakalisiwe;

3. Ukungcola okufana ne-graphite namafutha kuwela ku-cylinder extrusion;

4. Imikhiqizo ihamba nomunye nomunye, ukuze ubuso bukhishwe futhi ukugeleza kwe-extrusion kungalingani, okubangela ukuthi imikhiqizo ingagelezi emgqeni oqondile, okuholela emihumeni phakathi kwezinto kanye nendlela yokuqondisa kanye ne-worktable.

Indlela yokuvimbela

1. Hlola bese ushintsha isikhunta esingafanelekile ngesikhathi;

2. Lawula izinga lokushisa lokushisa loboya;

3. Qinisekisa ukuthi ingaphezulu le-extrusion cylinder noboya lihlanzekile futhi lomile;

4. Lawula isivinini se-extrusion ukuze uqinisekise isivinini esifanayo.

XI.Isikhunta izimpawu

Lona umkhondo wokungalingani kwe-longitudinal ebusweni bomkhiqizo okhishiwe, futhi yonke imikhiqizo ekhishiwe inamamaki okufa ngamazinga ahlukahlukene.

Imbangela eyinhloko yezimpawu zesikhunta

Isizathu esiyinhloko: ibhande elisebenzayo lesikhunta alikwazi ukufeza ukushelela okuphelele.

Indlela yokuvimbela

1. Qinisekisa ukuthi ingaphezulu lebhande elisebenzayo lesikhunta lihlanzekile, libushelelezi futhi alinayo imiphetho ebukhali;

2. Ukwelashwa kwe-nitriding okunengqondo ukuze kuqinisekiswe ubulukhuni obuphezulu bobuso;

3. Lungisa kahle isikhunta;

4. Ibhande elisebenzayo kufanele lenziwe ngendlela enengqondo, futhi ibhande elisebenzayo akufanele libe lide kakhulu.

XII.Sonta, goba, qhweba

Isenzakalo lapho ingxenye ephambanayo yomkhiqizo okhishiwe iphambukiswe nge-angular ngendlela ye-longitudinal ibizwa ngokuthi i-twisting.Isenzakalo sokuthi umkhiqizo ugobile ohlangothini lwe-longitudinal noma umumo wommese awuqondile ubizwa ngokuthi ukugoba.Isenzo esiqhubekayo sokungaguquguquki esenzeka ohlangothini lwe-longitudinal yomkhiqizo sibizwa ngokuthi igagasi.

Izimbangela eziyinhloko zokusonteka, ukugoba, namagagasi

1. Ukuklanywa nokuhlelwa kwezimbobo zokufa akukuhle, noma ukusatshalaliswa kosayizi webhande elisebenzayo akunangqondo;

2. Ukunemba kabi kwemishini yezimbobo zokufa;

3. Umhlahlandlela ofanele awufakiwe;

4. Ukulungiswa kwesikhunta okungafanele;

5. Ukushisa okungalungile kwe-extrusion nesivinini;

6. Umkhiqizo awuqondiswa ngaphambili ngaphambi kokwelashwa kwesixazululo;

7. Ukupholisa okungalingani ngesikhathi sokwelashwa kokushisa okuku-inthanethi.

Indlela yokuvimbela

1. Izinga eliphezulu lokuklama nokukhiqiza isikhunta;

2. Faka umhlahlandlela ofanele, ukudonsa kanye nokukhipha;

3. Sebenzisa ukugcoba kwendawo, ukulungisa isikhunta kanye nokuphambukisa noma ushintshe ukwakheka kwembobo ye-shunt ukuze ulungise izinga lokugeleza kwensimbi;

4. Lungisa ngokufanele izinga lokushisa nesivinini se-extrusion ukuze wenze i-deformation ibe yinto efanayo;

5. Yehlisa ngokufanelekile izinga lokushisa lokwelashwa kwesisombululo noma ukhuphule izinga lokushisa lamanzi ukuze uthole ukwelashwa kwesixazululo;

6. Qinisekisa ukupholisa okufanayo ngesikhathi sokucisha i-inthanethi.

XIII.Ukugoba kanzima

Ukugoba kungazelelwe komkhiqizo okhishwe endaweni ethile ohlangothini lobude kubizwa ngokuthi ukugoba okuqinile.

Imbangela eyinhloko yokugoba kanzima

1. Isivinini sokukhipha isivinini esingalingani, ukuguquka okungazelelwe kusuka esivinini esiphansi kuya esivinini esikhulu, noma ukuguquka kungazelelwe ukusuka esivinini ukuya kwesivinini esiphansi, nokuma kungazelelwe;

2. Hambisa ngokuqinile umkhiqizo ngesikhathi senqubo yokukhipha;

3. Indawo yokusebenza ye-extruder ayilingani.

Indlela yokuvimbela

1. Ungami ngokungahleliwe noma ushintshe isivinini sokukhipha ngokuzumayo;

2. Ungayisusi iphrofayili ngokuzumayo ngesandla;

3. Qinisekisa ukuthi itafula lokukhipha liyisicaba futhi ithebula le-roller yokukhipha libushelelezi, ngaphandle kwezinto zangaphandle, futhi umkhiqizo ohlangene awuvimbeli.

XIV.Ama-noodle we-Hemp

Lokhu kuyisici esingaphezulu somkhiqizo okhishwe, okusho ukuthi ubuso bomkhiqizo bungama-flakes aqhubekayo, imihuzuko yamabala, imigodi, ubhontshisi wensimbi, njll. ngokungalingani okuncane.

Imbangela enkulu ye-pockmark

1. Ukuqina kwesikhunta akwanele noma ubulukhuni abulingani;

2. Izinga lokushisa lokukhipha liphezulu kakhulu;

3. Isivinini sokukhipha sishesha kakhulu;

4. Ibhande elisebenzayo lesikhunta lide kakhulu, liqinile noma linamathele ngensimbi;

5. Uvolo okhishiwe mude kakhulu.

Indlela yokuvimbela

1. Thuthukisa ubulukhuni nobulukhuni bebhande lokusebenza isikhunta;

2. Shisisa isilinda sokukhipha kanye nengot ngokwemithethonqubo, futhi usebenzise isivinini esifanelekile sokukhipha;

3. Yakha isikhunta ngendlela enengqondo, unciphise ubulukhuni obungaphezulu bebhande elisebenzayo, futhi uqinise ukuhlolwa kwendawo, ukulungisa nokupholisha;

4. Sebenzisa ubude be-ingot obufanele.

XV.Ukucindezela insimbi

Phakathi nenqubo ye-extrusion, ama-chips ensimbi acindezelwa ebusweni bomkhiqizo, okubizwa ngokuthi ukucindezela kwensimbi.

Izimbangela eziyinhloko zokungena kwensimbi:

1. Iziphetho zoboya zinephutha;

2. Ingaphakathi loboya linamathele ensimbi noma amafutha okugcoba aqukethe izinsalela zensimbi nokunye ukungcola;

3. Isilinda se-extrusion asihlanzwa, futhi kunezinye izinsalela zensimbi;

4. Ingot icwiliswa kwezinye izinto zensimbi zangaphandle;

5. Kukhona ukufakwa kwe-slag eboyeni.

Indlela yokuvimbela

1. Susa ama-burrs eboyeni;

2. Qinisekisa ukuthi ingaphezulu loboya namafutha okugcoba kuhlanzekile futhi komile;

3. Hlanza imfucumfucu yensimbi kusikhunta nesilinda sokukhipha;

4. Khetha uvolo wezinga eliphezulu.

XVI.Ukucindezela okungeyona insimbi

Udaba lwangaphandle olufana nomnyama wetshe lucindezelwa endaweni yangaphakathi nangaphandle yomkhiqizo okhishiwe, obizwa ngokuthi ukuhlehlisa okungeyona insimbi.Ngemuva kokuthi udaba lwangaphandle lukhishwe, indawo yangaphakathi yomkhiqizo izobonisa ukucindezelwa kwamasayizi ahlukene, okuzobhubhisa ukuqhubeka kobuso bomkhiqizo.

Isizathu esiyinhloko sokungenwa kwensimbi

1. Ubukhulu bezinhlayiyana zegraphite buyi-coarse noma i-agglomerated, equkethe umswakama noma amafutha, futhi ukugqugquzela akulingani;

2. I-flash point yamafutha e-cylinder iphansi;

3. Isilinganiso samafutha e-cylinder ne-graphite akulungile, futhi kune-graphite eningi kakhulu.

Indlela yokuvimbela

1. Sebenzisa i-graphite efanelekayo futhi uyigcine yomile;

2. Hlunga futhi usebenzise amafutha okugcoba afanelekayo;

3. Lawula isilinganiso samafutha okugcoba kanye negraphite.

XVII.Ukugqwala komhlaba

Imikhiqizo enwetshiwe engakaze yenzelwe ukwelashwa okungaphezulu, ingaphezulu lomkhiqizo okhishiwe, ngemva kokusabela kwamakhemikhali noma kwe-electrochemical ne-medium yangaphandle, kubangela isici esibangelwa ukulimala kwendawo kwendawo, okubizwa ngokuthi ukugqwala kwendawo.Ingaphezulu lomkhiqizo ogqwalile lilahlekelwa ukucwebezela kwayo kwensimbi, futhi ezimeni ezinzima, imikhiqizo yokugqwala empunga-mhlophe ikhiqizwa ngaphezulu.

Imbangela enkulu yokugqwala kwendawo

1. Umkhiqizo uchayeka emithonjeni eyonakalisayo efana namanzi, i-asidi, i-alkali, usawoti, njll. ngesikhathi sokukhiqiza, ukugcinwa nokuthuthwa, noma upakwe endaweni enomswakama isikhathi eside;

2. I-alloy composition ratio engalungile;

Indlela yokuvimbela

1. Gcina ingaphezulu lomkhiqizo nendawo yokukhiqiza nendawo yokubeka ihlanzekile futhi yomile;

2. Lawula okuqukethwe kwezakhi ku-alloy.

XVIII.Ikhasi lewolintshi

Ingaphezulu lomkhiqizo okhishiwe linemibimbi engalingani njengekhasi lewolintshi, elibuye laziwe ngokuthi imibimbi engaphezulu.Kubangelwa izinhlamvu ezimahhadla ngesikhathi sokukhipha.Lapho okusanhlamvu kushubile, imibimbi iba sobala kakhulu.

Imbangela eyinhloko yekhasi lewolintshi

1. Isakhiwo se-ingot asilingani futhi ukwelashwa kwe-homogenization akwanele;

2. Izimo ze-extrusion azinangqondo, futhi izinhlamvu zemikhiqizo eqediwe ziqinile;

3. Inani lokwelula nokuqondisa likhulu kakhulu.

Indlela yokuvimbela

1. Lawula ngokunengqondo inqubo ye-homogenization;

2. I-deformation kufanele ifane ngangokunokwenzeka (lawula izinga lokushisa le-extrusion, isivinini, njll.)

3. Lawula inani lokulungiswa kwengcindezi lingabi likhulu kakhulu.

XIX.Akulingani

Ngemuva kokukhishwa, indawo lapho ubukhulu bomkhiqizo bushintsha endizeni ibonakala iyi-concave noma i-convex.Ngokuvamile, ayikwazi ukubonwa ngeso lenyama.Ngemuva kokwelashwa okungaphezulu, izithunzi ezinhle noma izithunzi zamathambo ziyavela.

Imbangela eyinhloko yokungalingani

1. Ibhande elisebenzayo lesikhunta aliklanyelwe kahle, futhi ukulungiswa kwesikhunta akukho endaweni;

2. Ubukhulu bembobo ye-shunt noma i-pre-chamber ayifaneleki, futhi amandla okudonsa noma okwandisa iphrofayili endaweni yesiphambano kubangela ushintsho oluncane endizeni;

3. Inqubo yokupholisa ayilingani, futhi isivinini sokupholisa sengxenye enodonga oluwugqinsi noma ingxenye ephambanayo ihamba kancane, okuholela emazingeni ahlukene okushwabana nokuguqulwa kwendiza phakathi nenqubo yokupholisa;

4. Ngenxa yomehluko omkhulu wokuqina, umehluko phakathi kwengxenye enezindonga eziwugqinsi noma inhlangano yendawo yoshintsho nezinye izingxenye zenhlangano uyakhula.

Indlela yokuvimbela

1. Ukwenza ngcono izinga lokuklanywa kwesikhunta, ukukhiqiza kanye nokulungisa isikhunta;

2. Qinisekisa isivinini sokupholisa esifanayo.

XX.Iphethini yokudlidliza

Lesi yisici se-periodic streak esiguquguqukayo ukuya phezulu komkhiqizo okhishiwe.Ibonakala ngemigqa evundlile eqhubekayo yezikhathi ebusweni bomkhiqizo, futhi ijika lomugqa lihambisana nokuma kwebhande elisebenzayo lesikhunta, futhi ezimeni ezinzima, kuba nokuzwakala okusobala kwe-bumpy.

Imbangela enkulu yokudlidliza

1. I-extrusion shaft iqhubekela phambili futhi inyakaze ngenxa yezizathu zemishini, okubangela ukuba insimbi inyakaze lapho igeleza iphuma emgodini;

2. Insimbi iyanyakaza lapho igeleza iphuma emgodini wokufa ngenxa yesikhunta;

3. Iphedi yokusekela isikhunta ayifanele, ukuqina kwesikhunta akukuhle, futhi ukudlidliza kwenzeka lapho amandla e-extrusion eguquguquka.

Indlela yokuvimbela

1. Sebenzisa isikhunta esifanelekayo;

2. Amaphedi okusekela afanelekile kufanele asetshenziswe lapho isikhunta sifakiwe;

3. Lungisa izinto zokusebenza.

XXI, Okuxubile

Isizathu esiyinhloko sokufakwa

Njengoba i-inclusion billet inensimbi noma okungezona ezensimbi, ayizange itholakale kunqubo yangaphambilini, futhi yahlala phezu noma ngaphakathi komkhiqizo ngemva kokukhishwa.

Indlela yokuvimbela

Qinisa ukuhlolwa kwe-billet (kuhlanganise nokuhlolwa kwe-ultrasonic) ukuze uvimbele i-billet equkethe i-metal noma i-non-metallic inclusions ekungeneni inqubo ye-extrusion.

XXII, Izimpawu zamanzi

Izimpawu zomugqa wamanzi okhanyayo omhlophe noma omnyama ongajwayelekile endaweni yomkhiqizo zibizwa ngokuthi ama-water mark.

Imbangela eyinhloko yezimpawu zamanzi

1. Ukomisa akukuhle ngemva kokuhlanza, futhi kukhona umswakama osele phezu komkhiqizo;

2. Umswakama osele phezu komkhiqizo obangelwa imvula nezinye izizathu awuzange uhlanzwe ngesikhathi;

3. Uphethiloli wesithando somlilo esiguga uqukethe amanzi, futhi amanzi ajiya phezu komkhiqizo ngesikhathi sokupholisa umkhiqizo ngemva kokuguga;

4. Uphethiloli wesithando somlilo esigugayo awuhlanzekile, futhi ubuso bomkhiqizo bugqwala yi-sulphur dioxide ngemva kokusha noma ukungcoliswa uthuli;

5. Indawo yokucisha ingcolile.

Indlela yokuvimbela

1. Gcina ubuso bomkhiqizo bomile futhi buhlanzekile;

2. Lawula umswakama kanye nokuhlanzeka kwezindleko zokuguga;

3. Ukuqinisa ukuphathwa kwe-quenching medium.

XXIII.Igebe

Umbusi ubekwe phezulu ngokuvundlile endizeni ethile yomkhiqizo okhishiwe, futhi kukhona igebe elithile phakathi kwerula nendawo engaphezulu, ebizwa ngokuthi igebe.

Imbangela enkulu yegebe

Ukugeleza kwensimbi okungalingani ngesikhathi sokukhishwa noma ukuqedwa okungalungile nokuqondisa imisebenzi.

Indlela yokuvimbela

Dizayina futhi ukhiqize isikhunta ngokunengqondo, qinisa ukulungisa isikhunta, futhi ulawule izinga lokushisa le-extrusion kanye nesivinini sokukhipha ngokuhambisana ngokuqinile nemithethonqubo.

XXIV, ukujiya kodonga olungalingani

Imikhiqizo enwetshiwe yosayizi ofanayo inezindonga ezincane noma eziwugqinsi esigabeni esifanayo noma isiqondiso se-longitudinal, futhi lo mkhuba ubizwa ngokuthi ukushuba kodonga olungalingani.

Imbangela eyinhloko yokuqina kodonga olungalingani

1. Ukwakhiwa kwesikhunta akunangqondo, noma ithuluzi kanye nokuhlanganiswa kwesikhunta akufanelekile;

2. I-extrusion cylinder kanye nenaliti ye-extrusion ayikho emgqeni ofanayo, okwenza i-eccentricity;

3. I-lining ye-extrusion cylinder igqoke kakhulu, futhi isikhunta asikwazi ukumiswa ngokuqinile, okuholela eccentricity;

4. Ubukhulu obungalingani bodonga lwe-ingot engenalutho ngokwayo abukwazi ukuqedwa ngemva kokukhipha kokuqala nokwesibili.Ubukhulu bodonga obungalingani boboya ngemva kokukhishwa abususwa ngemva kokugoqa nokwelula;

5. Amafutha okugcoba asetshenziswa ngokungalingani, okwenza insimbi igeleze ngokungalingani.

Indlela yokuvimbela

1. Lungiselela ukuklama kanye nokukhiqizwa kwamathuluzi nezibunjwa, futhi uhlanganise ngokunengqondo futhi ulungise;

2. Lungisa isikhungo se-extruder kanye ne-extrusion die;

3. Khetha izikhala ezifanelekayo;

4. Ukulawula okunengqondo kokushisa kwe-extrusion, isivinini sokukhipha kanye neminye imingcele yenqubo.

XXV.Nweba (kanye) nomlomo

Isici sokuthi izinhlangothi ezimbili zemikhiqizo yephrofayili ekhishiwe njenge-groove kanye nesimo se-I zithambekele ngaphandle kubizwa ngokuthi i-flaring, futhi isici esithambekele ngaphakathi sibizwa ngokuthi i-parallel opening.

Izimbangela eziyinhloko zokwanda (ukuhlanganisa)

1. Izinga lokugeleza kwensimbi "lemilenze" emibili (noma "umlenze" owodwa) womkhombe noma amaphrofayili afanayo noma amaphrofayili amise okwe-I awalingani;

2. Izinga lokugeleza kwebhande lokusebenza ezinhlangothini zombili ze-groove bottom plate alilingani;

3. Umshini wokwelula ongalungile;

4. Ngemuva kokuthi umkhiqizo uphume emgodini wesikhunta, ukwelashwa kwesixazululo se-inthanethi kupholiswe ngokulinganayo.

Indlela yokuvimbela

1. Lawula ngokuqinile isivinini se-extrusion kanye nezinga lokushisa lokukhipha;

2. Qinisekisa ukufana kokupholisa;

3. Dizayina futhi ukhiqize isikhunta ngendlela efanele;

4. Lawula ngokuqinile izinga lokushisa nesivinini se-extrusion, futhi ufake ithuluzi futhi ufe ngendlela efanele.

XXVI.Izimpawu zokuqondisa

Ama-helical streaks akhiqizwa lapho umqulu ophezulu womkhiqizo okhishiwe uqondiswa ubizwa ngokuthi ama-straightening marks, futhi izimpawu zokuqondisa azikwazi ukugwenywa kunoma yimuphi umkhiqizo oqondiswe umqulu ophezulu.

Imbangela enkulu yamamaki okuqondisayo

1. Kukhona imiphetho ebusweni be-roller ye-roller yokuqondisa;

2. Ukugoba komkhiqizo kukhulu kakhulu;

3. Ukucindezela okukhulu;

4. I-engeli yerola yokuqondisa inkulu kakhulu

5. Umkhiqizo une-ovality enkulu.

Indlela yokuvimbela

Thatha izinyathelo ezifanele ukulungisa ngokuhambisana nesizathu.

XXVII.Izimpawu zokumisa, okuvelayo okusheshayo, izimpawu zokuluma

Misa i-extrusion ngesikhathi sokukhipha ukuze ukhiqize imivimbo ebusweni bomkhiqizo kanye ne-perpendicular to the extrusion direction, ebizwa ngokuthi ama-stop marks;ulayini noma imigqa yemigqa ebusweni bomkhiqizo kanye ne-perpendicular to extrusion direction during extrusion , eyaziwa ngokuthi yizimpawu zokulunywa noma okuvelayo okusheshayo (okuvame ukwaziwa ngokuthi "izimpawu zokupaka zomgunyathi")

Ngesikhathi se-extrusion, okunamathiselwe okunamathiselwe ngokuzinzile ebusweni bebhande elisebenzayo kukhishwa ngokushesha futhi kunamathele ebusweni bomkhiqizo okhishiwe ukuze zenze amaphethini.Imigqa evundlile yebhande elisebenzayo elivela lapho i-extrusion imisiwe ibizwa ngokuthi izimpawu zokupaka;imivimbo evela ngesikhathi senqubo ye-extrusion ibizwa ngokuthi okuvelayo okusheshayo noma izimpawu zokuluma, futhi izokwenza umsindo ngesikhathi sokukhipha.

Izimbangela eziyinhloko zama-stop marks, amamaki asheshayo, nama-bite marks

1. Ukushisa okungalingani kokushisa kwe-ingot noma ukushintsha okungazelelwe kwesivinini sokukhipha kanye nokucindezela;

2. Izingxenye eziyinhloko zesikhunta aziklanyelwe kabi futhi zakhiwe, noma umhlangano awulingani futhi kunezikhala;

3. Kukhona amandla angaphandle perpendicular isiqondiso extrusion;

4. I-extruder ayihambi kahle, futhi kukhona okwenzekayo kokukhasa.

Indlela yokuvimbela

1. Ukushisa okuphezulu, isivinini esincane kanye ne-extrusion efanayo, amandla e-extrusion ahlala ezinzile;

2. Vimbela amandla angaphandle ekuqondeni kwe-extrusion mpo ekusebenzeni kumkhiqizo;

3. Idizayini enengqondo yamathuluzi kanye nesikhunta, ukukhetha okulungile kwezinto zokwakha isikhunta, ukufanisa usayizi, amandla nobulukhuni.

XXVIII.Imihuzuko endaweni engaphakathi

Imihuzuko endaweni engaphakathi yomkhiqizo okhishwe ngesikhathi senqubo yokukhipha ibizwa ngokuthi imihuzuko yangaphakathi.

Imbangela eyinhloko yokuhuzuka kwendawo yangaphakathi

1. Inaliti yokukhishwa inamathele ngensimbi;

2. Izinga lokushisa lenaliti ye-extrusion liphansi;

3. Izinga eliphezulu lenaliti ye-extrusion limpofu futhi kukhona ama-bumps;

4. Izinga lokushisa le-extrusion nesivinini azilawulwa kahle;

5. Isilinganiso esingalungile se-lubricant extrusion;

Indlela yokuvimbela

1. Khulisa izinga lokushisa le-extrusion cylinder kanye nenaliti ye-extrusion, futhi ulawule izinga lokushisa le-extrusion nesivinini sokukhipha;

2. Qinisa ukuhlungwa kwamafutha okugcoba, hlola noma ubuyisele uwoyela ongcolile njalo, futhi usebenzise uwoyela ngokulinganayo nangokufanele;

3. Gcina ingaphezulu loboya lihlanzekile;

4. Faka esikhundleni isikhunta esingafanelekile nezinaliti zokukhipha ngesikhathi, futhi ugcine isikhunta se-extrusion sihlanzekile futhi sibushelelezi.

XXX.Ezinye izici

Ngamafuphi, ngemuva kokwelashwa okuphelele, izinhlobo ezingama-30 zokukhubazeka kwemikhiqizo eshiwo ngenhla ye-aluminium alloy extrusion ingaqedwa ngempumelelo, ikhwalithi ephezulu, isivuno esiphezulu, impilo ende, kanye nomkhiqizo omuhle, ukudala uphawu, ukuletha ubungqabavu nokuchuma ibhizinisi, kanye nezinzuzo ezibalulekile zobuchwepheshe nezomnotho.

XXX.Ezinye izici

Ngamafuphi, ngemuva kokwelashwa okuphelele, izinhlobo ezingama-30 zokukhubazeka kwemikhiqizo eshiwo ngenhla ye-aluminium alloy extrusion ingaqedwa ngempumelelo, ikhwalithi ephezulu, isivuno esiphezulu, impilo ende, kanye nomkhiqizo omuhle, ukudala uphawu, ukuletha ubungqabavu nokuchuma ibhizinisi, kanye nezinzuzo ezibalulekile zobuchwepheshe nezomnotho.

Isikhathi sokuthumela: Aug-14-2022