Ukuthuthukiswa okuqhubekayo nokwenziwa okusha kobuchwepheshe bokuncibilika kwe-aluminium nokusakaza

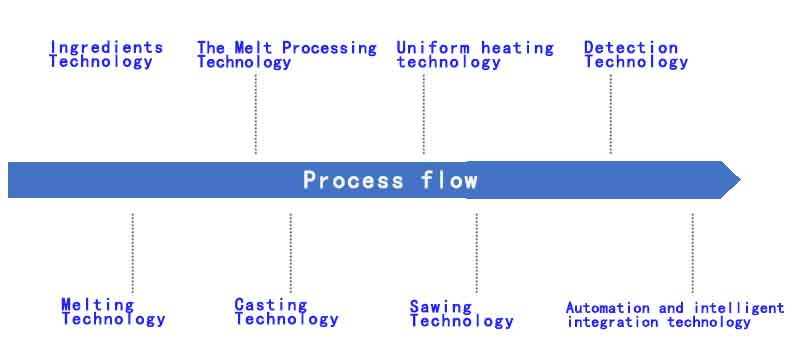

Ubuchwepheshe bokuncibilika kwe-aluminium kanye nokubunjwa ngokuyinhloko bubhekisela kubuchwepheshe obuhlukahlukene obuhilelekile ekukhiqizeni amashidi, umugqa, ucwecwe kanye neshubhu, induku kanye nezikhala zephrofayela.Ubuchwepheshe obufana nokucwiliswa emanzini, ukusaha, ukuhlola kanye ne-automation kanye nokuhlanganiswa okuhlakaniphile.Njengamanje, ukucushwa kwemishini eyisisekelo kakhulu yendawo yokusebenzela yokuphonsa ihlanganisa isithando somlilo esincibilikayo (noma isithando somlilo se-aluminium nesithando somlilo), indawo yokuhlanza impahla, uhlelo lokucubungula ku-inthanethi, umshini wokuphonsa, njll.

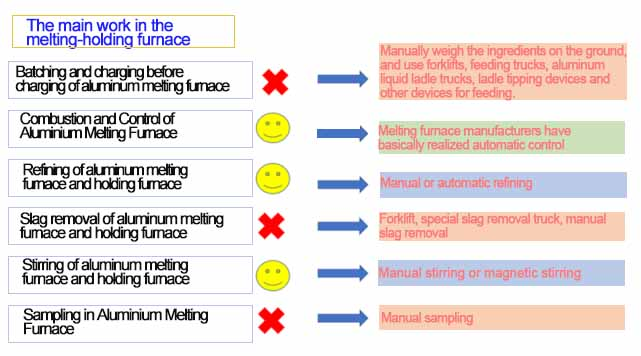

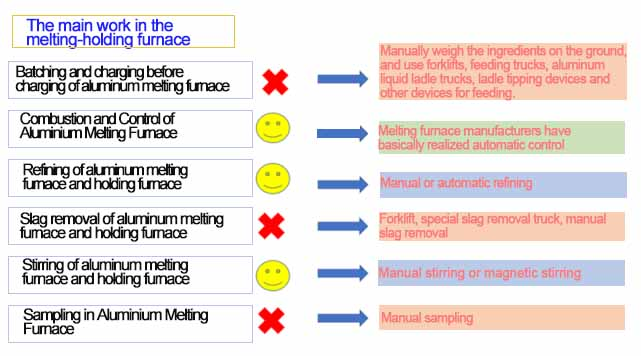

Kusukela esimweni sangempela sokukhiqiza se-workshop yokuphonsa, imisebenzi eyinhloko ihlanganisa ukuphakela, ukususwa kwe-slag, ukuphakela, ukucwengisiswa, ukulungisa isikhunta, ukuhlanza, ukuphakamisa, ukuthutha, ukubeka, ukulayisha nokukhipha, ukulinganisa, ukulayisha, njll Ngaphezu kwalokho, kukhona futhi Kukhona okuphakelayo okuwuketshezi, okuphakelayo okuqinile, ukucwenga ohlangothini lwesithando somlilo nokunye.Ekusebenzeni kwangempela, ukutholwa kokuvuza kwe-aluminium yamanje kanye nokuxhunywa esigabeni sokulingisa kusadinga umsebenzi wezandla, odinga umsebenzi omkhulu kanye nesici esiyingozi enkulu.Ngaphezu kwalokho, imisebenzi eyenziwa ngesandla nayo iyadingeka ukuze kuhlanzwe futhi kugcinwe isikhunta ngemva kokuphela.Uma kuqhathaniswa, umsebenzi omningi ofana nokulawula okuzenzakalelayo nama-ingots alengayo usuxazululiwe.Ngemuva kokukhipha nokukhipha ama-ingots, ngetafula le-roller yokugcina, umshini wokusaha, isithando somlilo (okubandakanya igumbi lokucwiliswa, igumbi lokupholisa, imoto yokuphakela, njll.), ukupakisha okuzenzakalelayo kanye nohlelo lokupakisha (isitaki, isitaki, usuku lokudlulisa) Izimoto, njll. .), izitholi zokukhubazeka, ukukala, ukubhalisa, ukulayisha nezinye izinhlelo zengezwe uhlelo lwe-MES ukuxhuma yonke inqubo ukuze kuzuzwe ukukhiqizwa okukhaliphile nokuqhubekayo.

Ngakho-ke, okwamanje, kusenezinkinga ezifana nokumiswa kwemishini engalingani kanye nezixhumanisi ezingezinhle zokungena phakathi kwemigqa yokukhiqiza.Kodwa-ke, ngokuthuthukiswa kobuchwepheshe, ukusetshenziswa okuhlangene kanye nokuxhumana kwemishini okwamanje kuxhunywe ngezinhlelo ezahlukene zokuphatha, futhi ukusebenza kahle kokukhiqiza kuyathuthukiswa.Ithuthukisiwe, futhi inkundla yokucobelelana ngolwazi yokulingisa isithuthukile ebheke kwezobunhloli.

Kusukela esimeni samanje sokusetshenziswa kobuchwepheshe bokuncibilika kwe-aluminium nokusakaza, ubuchwepheshe obusetshenziswa njengamanje ikakhulukazi buhlanganisa ubuchwepheshe bokushisa obuncibilikayo, ubuchwepheshe bokucubungula ukuncibilika, ubuchwepheshe bokuphonsa, nobunye ubuchwepheshe be-workshop.Ubuchwepheshe bokushisa obuncibilikayo obusetshenziswa kakhulu buwukushisa okuvuselelayo kanye nokushiswa kokushisa okunesivinini esikhulu ekushisiseni kwegesi, ngaphezu kokushisisa kukagesi nokushisa okujikelezayo.Ubuchwepheshe bokwelashwa kwe-Melt buhlanganisa ukwelashwa kwangaphambili kwesithando somlilo, ukwelashwa esithandweni somlilo, ukuchithwa kwegesi ku-inthanethi, ukususwa kwe-slag, ukucolisiswa okusanhlamvu nobunye ubuchwepheshe.Ubuchwepheshe bokusakaza buhlanganisa ingot eyisicaba, ingot eyindilinga, ubuchwepheshe be-casting kanye ne-rolling strip, kanye nobunye ubuchwepheshe be-workshop buhlanganisa ubuchwepheshe bokucwiliswa, ubuchwepheshe bokupholisa, ubuchwepheshe bokusaha nokunye.

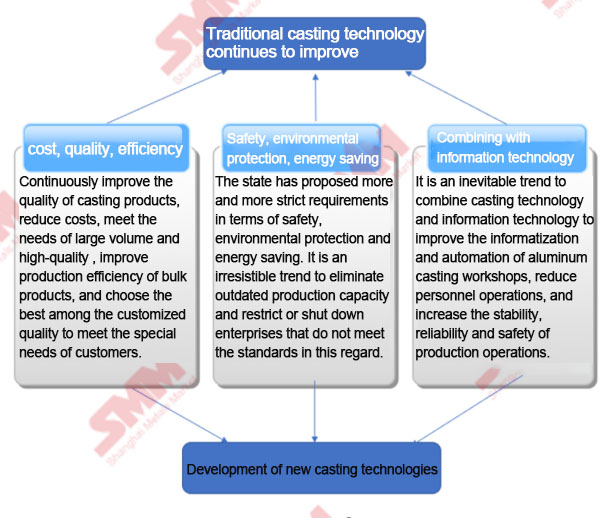

Njengamanje, ukuthuthukiswa kwamanje kobuchwepheshe bokusakaza kubangelwa ikakhulukazi ukuhlalisana kobuchwepheshe bokuphonsa okuningi, futhi izidingo zemikhiqizo ngokwezindleko, ikhwalithi nokusebenza kahle ziphezulu kakhulu kunangaphambili, kuyilapho izidingo zokuvikelwa kwemvelo, ukonga amandla nokuphepha. aqiniswa kancane kancane.Njengoba ubuchwepheshe obusha buqhubeka buvela, ubuchwepheshe obuphelelwe yisikhathi buqedwa kancane kancane.

Ngezidingo zokuncintisana embonini, ukulawulwa nokuqondiswa kwezinqubomgomo zikazwelonke, kanye nokuthuthukiswa okuqhubekayo kobuchwepheshe bokusakaza, akunaki nje kuphela ukwehlisa izindleko, ukuthuthukisa ikhwalithi yomkhiqizo, kanye nokwenza ngcono ukusebenza kahle kokukhiqiza, kodwa futhi kunaka kakhulu ukuvikelwa kwemvelo, izidingo zokonga ugesi kanye nokuphepha.Inhlanganisela nobuchwepheshe bolwazi isiphenduke inkambiso engenakugwemeka.

Ukwehliswa kwezindleko, ukuthuthukisa ukusebenza kahle, ukuvikelwa kwemvelo nokonga amandla kuyizikhombisi-ndlela eziyinhloko zokuthuthukiswa kobuchwepheshe obusha be-aluminium

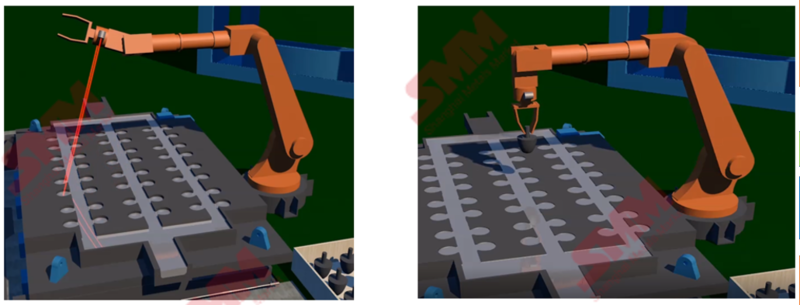

Phakathi kobuchwepheshe bokudla nokususwa kwe-slag, kukhona ikakhulukazi izimoto zokuphakela ezizenzakalelayo kanye nezimoto ezizenzakalelayo zokususa i-slag.Isetshenziselwa ukusebenza kokwengeza izinto eziqinile, izinto eziwuketshezi kanye ne-slag skimming ngaphambi kwesithando somlilo.

Idivayisi yokususa i-alkali kubuchwepheshe bokucubungula ukuncibilika isetshenziselwa ukulungiswa kwangaphambili kwe-electrolyte phambi kwesithando somlilo, futhi ubuchwepheshe bokucwenga imoto yokucwenga busetshenziswa ngaphambili kwesithando esikhundleni sokucwenga ngesandla ukuze kuthuthukiswe ukuphepha.Idivayisi ye-rotary degassing yesithando somlilo isetshenziselwa ikakhulukazi ukucwenga esithandweni, okungadingi ukungenelela komuntu, ithuthukisa ngokuphumelelayo ukusebenza kahle, futhi iphinde ithuthukise ukuphepha.Ngaphezu kwalokho, i-electromagnetic filtration

idivayisi isetshenziselwa ikakhulukazi ukuhlunga okuku-inthanethi, okunobuhle bokunemba okuphezulu kokuhlunga, ngokuyisisekelo akukho ukungcola okwethulwayo, nokuqaqa kalula nokufaka.Idivayisi ye-ultrasonic degassing ingakwazi ukubona ukwethulwa kokungabi nakungcola, izinga lokususwa kwe-hydrogen liphezulu njenge-70%, futhi okusanhlamvu kungacwengwa ngenkathi kucwengwa.

Ngaphansi kwezimfuneko eziyisisekelo zokuqhubeka nokuthola ukuncibilika namabhilidi engxubevange ye-aluminium yekhwalithi ephezulu, ubuchwepheshe bokuncibilika nokusakaza budinga ukuqhubeka buhlangabezane nezimfuneko zokusebenza kahle komkhiqizo omningi kanye nekhwalithi yomkhiqizo eyenziwe ngokwezifiso.Ukuthandwa kwe-automation ye-workshop kanye nokukhiqiza okuhlakaniphile kungathuthukisa kakhulu ukusebenza kahle kokukhiqiza futhi kuhlangabezane nezidingo zemikhiqizo eminingi.Ngasikhathi sinye, ukusheshisa ukuthuthukiswa kobuchwepheshe bakamuva bokuhlanza incibilike kanye nobuchwepheshe bokusakaza kungathuthukisa ngempumelelo izidingo zekhwalithi yemikhiqizo eyenziwe ngokwezifiso, futhi ekugcineni kwengezwe ubuhlakani kanye ne-automation.Ubuchwepheshe obudidiyelwe buthuthukisa ngokugcwele ukuzinza, ukuphepha kanye nokwethembeka kokukhiqizwa kweshabhu, futhi kuqinisekisa isimo esithuthukisiwe seshabhu mayelana nokuvikelwa kwemvelo nokonga amandla.

Isikhathi sokuthumela: Aug-15-2022