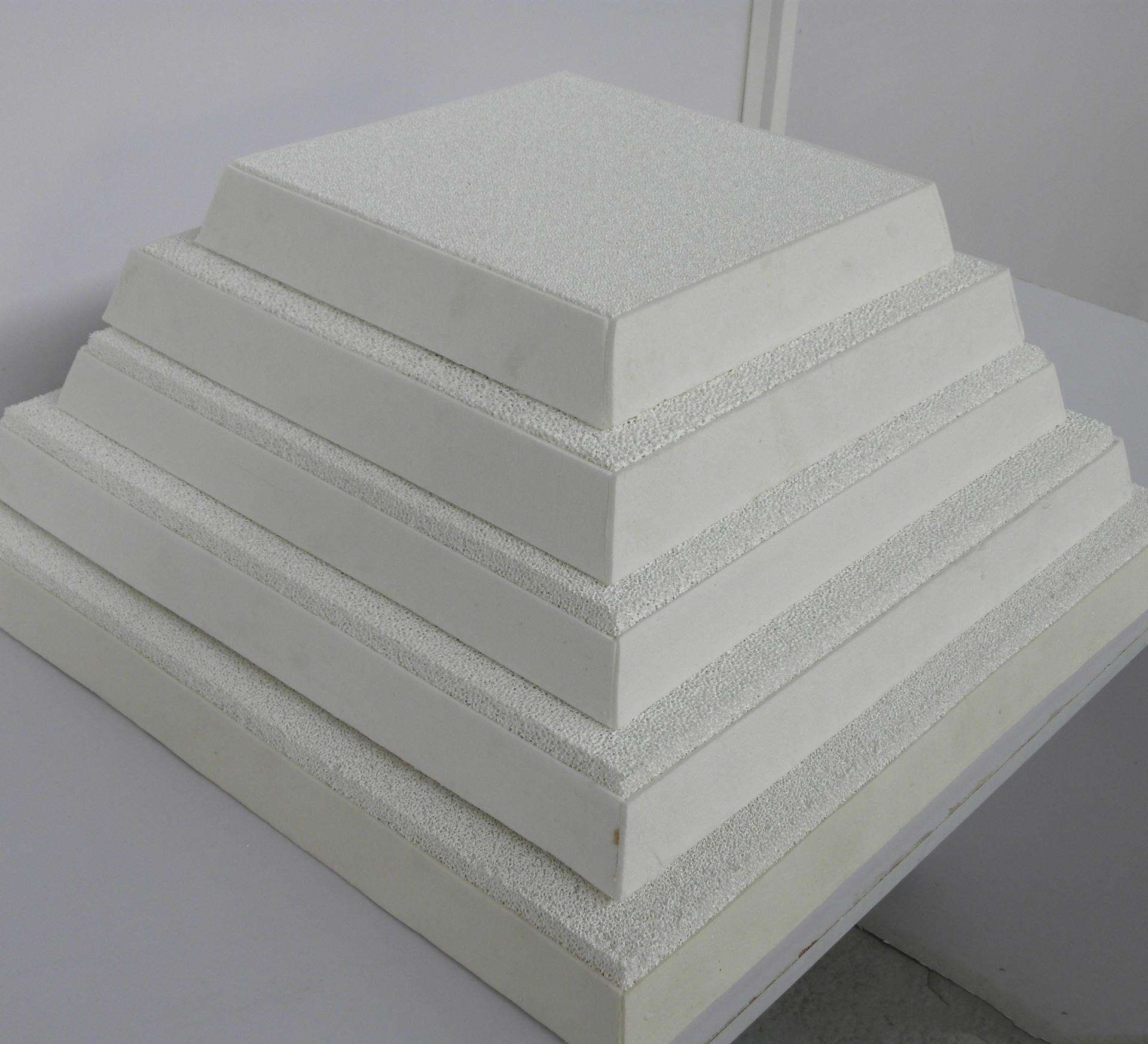

I-Refractory Alumina I-Porous Ceramic Foam Filter Plate Ye-Aluminium Encibilikisiwe

Imiyalo yokusetshenziswa kwepuleti yokuhlunga ye-ceramic foam:

Hlola futhi uhlanze imfucumfucu ebusweni bebhokisi lokuhlunga ukuze ugcine ibhokisi lokuhlunga lihlanzekile futhi lingenawo umonakalo.

Faka kahle ipuleti lokuhlunga ebhokisini lokuhlunga, bese ucindezela i-gasket evalayo eduze kwepuleti lokuhlunga ngesandla ukuze uvimbele uketshezi lwe-aluminium ukuthi lungadluleli noma luntante.

Shisisa kuqala ibhokisi lesihlungi nepuleti lokuhlunga ngokulinganayo ukuze ukwenze kusondele izinga lokushisa le-aluminium encibilikisiwe, futhi izinga lokushisa langaphambili lepuleti lokuhlunga alikho ngaphansi kuka-260℃.Ukushisa kuqala ukuze kukhishwe amanzi akhangisiwe kusiza ukuvula usayizi wokuqala wesihlungi sembotshana ngokuphazima kweso, kuvimbele ukuvaleka kwembotshana yepuleti lokuhlunga ngenxa yokwanda nokufinyela okushisayo.Ukushisa kukagesi noma kwegesi kungasetshenziselwa ukushisa kuqala, futhi ukushisa okuvamile kuthatha imizuzu engu-15-30.

Lapho usakaza, naka izinguquko ze-aluminium hydraulic head, futhi ugcine isidingo esivamile sokugeleza koketshezi lwe-aluminium.Inhloko evamile yokucindezela kokuqala ngu-100-150mm.Lapho i-aluminium encibilikisiwe iqala ukudlula, ikhanda lokucindezela lizokwehla ngaphansi kwe-75-100mm, bese ikhanda lokucindezela lizokhula kancane kancane.

Phakathi nenqubo evamile yokuhlunga, gwema ukungqongqoza nokudlidliza ipuleti lokuhlunga.Ngesikhathi esifanayo, umshini wokuhlanza kufanele ugcwaliswe ngamanzi e-aluminium ukuze ugweme ukuphazamiseka okuningi koketshezi lwe-aluminium.

Ngemuva kokuhlunga, khipha ipuleti lokuhlunga ngesikhathi bese uhlanza ibhokisi lokuhlunga.

| Usayizi | Imodeli/ugqinsi (mm) | ppi | Ukupakisha |

| 12 intshi | 305/40 | 20,30,40,50,60 | 10pcs/ibhokisi |

| 12 intshi | 305/50 | 10pcs/ibhokisi | |

| 15 intshi | 381/40 | 6pcs/ibhokisi | |

| 15 intshi | 381/50 | 6pcs/ibhokisi | |

| 17 intshi | 432/50 | 6pcs/ibhokisi | |

| 20 intshi | 508/50 | 5pcs/ibhokisi | |

| 23 intshi | 584/50 | 5pcs/ibhokisi |